Penstocks are the most commonly used isolation devices. It requires practically no maintenance. It can have a cast iron body or a fabricated body with exchangeable sealing arrangement made of soft material. It can be manually operated or power operated.

Salient features of penstocks are:

- Exchangeable seals

- Manually or electrically operated

- Wall bolted frames (Cast Iron max. size of 2400 mm)

- Non-rising/Rising stem design

- Roller guided door for ease of operation

- Guides having adjustable wedges

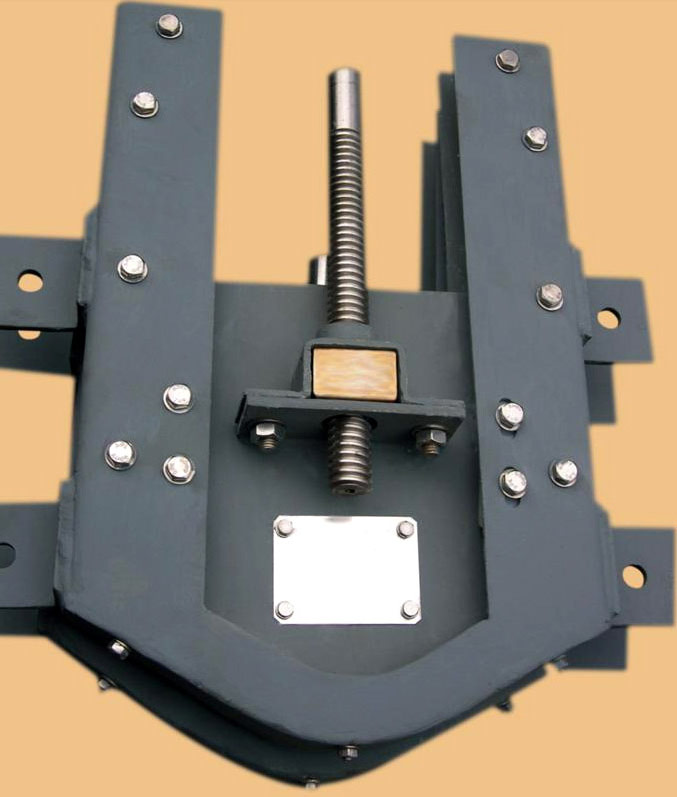

Penstocks have cast iron/welded steel frame, door and guides with seal clamping strips, rollers, bolts and SS adjustable wedges. Both frame and door are provided with replaceable seal. The stem is constructed of carbon steel or stainless steel, with a stainless steel spindle.

Frame

The frame is manufactured from cast-iron/stainless steel/galvanized steel. The flat backed design of the penstock gate makes it suitable for installation against a wall, by bolting and in recesses.

Door

The door is manufactured from cast-iron/stainless steel/galvanized steel and is designed for the specified maximum head. It is of robust construction suitably strengthened with ribs or trapezoidal ribbing dependent upon the specific use. The sealing strips are secured to the frame in such a way that liquid seepage between the sealing faces is eliminated.

Roller Assembly

All gates are designed with a wedging system. To reduce water forces for gate sizes above 600 mm, the door is guided by rollers. During the opening of the gate, a slope in the guide rail moves away the door from the sealing surface. The adjustable stepped wedging system ensures that when in closed position, the door is pressed against the sealing surface providing a watertight seal.

Guide Frame

Guides are made of the same material as the frame and the door. The guides are bolted to the machined surfaces of the frame and are designed for the specified maximum head. The length of the guides makes it possible to guide the rollers for a full opening of the door. The guides are capable of taking the entire thrust produced by the wedging action, even if the door is forced by unseating head pressure.

Thrust Nut

Each door is provided with a thrust-nut pocket. This pocket is bolted to the door and manufactured from the same material as the door. The thrust-nut pocket is designed to prevent any turning of the nut during operation and is capable of withstanding the operating forces. The thrust nut is made of brass or bronze.

Stem and Spindle

The gate is operated via a solid stem with a threaded spindle. Operating stems are sized to safely withstand stresses induced by normal operating forces. Stems are fabricated from solid stainless steel bars.

Drives for operation

For smaller sizes tee-key operating drives are possible. Floor stands of appropriate design for handwheel or with electric / pneumatic gear box are used for gate sizes above 600 mm.